中古 ASML Twinscan XT 1250D #9228718 を販売中

URL がコピーされました!

タップしてズーム

ID: 9228718

ウェーハサイズ: 12"

ヴィンテージ: 2004

ArF Scanner, 12"

Track pre-warning signal: APR

Input / Output conflicts: Avoid track

Type of wafer table on chuck 1 and 2: Zerodur

Wafer stage: Type 2

Wafer carrier: Right

(25) Wafers per carriers

Wafer stage types: Dual chuck

Lower docking plates

WS Balance mass: Stainless steel

WH Robot power amplifier: CPM 20

Wafer stage fast stiff X move electronics

Wafer stage mirror block down electronics

Interferometer axis version at exposure: 3 Plus, 1 Axis

Wafer handling pneumatic

Chuck 1 and 2, 12"

Docking wheels at WH unload

Docking plate height: Low

Carrier handler type: Mark I 300 FOUP

Wafer handling load: Double fold arms

Unload robot type: Z Stroke, 12 mm

Wafer handler WRT BF shifted in Z

Encoders measurement system: Hall sensors for zeroing

Reticle stage chuck type: Glued leaf spring

Type 2: Glued LS, Pneumatic GC, IFM / ENC

Reticle carrier: Right

Integrated reticle inspection system: PPD1 With IRIS1

Integrated reticle library: IRL

Reticle, 6"

Reticle carrier tag reader

Reticle stage long stroke motor type: Cobalt ferro 18 teeth

No closing disk

No enhancements in reticle monitor

Reticle stage long stroke config: Type 3

CoFe-18 Motor

SB Controller

Vacuum supply

Pneum GC

Reticle stage: Lens cooler box with anti-aliasing filter

Maximum reticle ID length: 24 Characters

Reticle stage measurement system on scan: HEIDENHAIN Encoder

RS Object field

Reticle exchange type: Retex E option

Reticle handler

Dynamic performance calculation: Mark 1

Stages sample rate: 5.0 kHz

Interferometer electronics

Capacitive Z-height sensor type: Dual Z sensor board

IFM Config at measure side: 8-Axes

Dose system: Test sequence 1

Depolarizer type: Fixed

Pupil qualification method: Center of gravity method

Unpolarized illumination amorph DOE

Validity range: Exact matching for UIP data

Active element: ALE

BMU Reading: DOE1 Plane

Lens type: 12

Light-source architecture: Laser

Light-source wave-length: 193 nm

Dose mapper

REMA Architecture: REMA C

Illuminator type: 120

AXICON Zoom architecture: ZZA / 120

Automated DOE exchanger / Architecture: 5 Slots MIP control

UNICOM / Architecture: Motor

Imaging electronics architecture: B Architecture

Attenuator type

Test table Z-axis: Worm wheel

PUPICOM / Architecture: DC Motor with gearbox

(5) Z Lens manipulators

Active lens element

Active element

(4) Semi-active X-Y lens manipulators

Setup sensor board

Imaging generic power amplifier

Imaging control rack configuration

Projection multiplexer board

LEC Rack in electronic architecture

Projection GPA configuration

(5) Lens NEXZ Manipulators

Spot sensor surface coating: Bilatal

Energy sensor: VLOC

Spot sensor chuck 1 and 2: VLOC

Uniformity improvement package

Pupil measurements with ILIAS

Beam control: Beam adjustment

Extended spot sensor match

(5) Rxms / (5) Ryms

Exchangeable last lens element

UV Shutter

Dose control hardware: ISB

Illuminator platform: Aerial 2

Test table architecture: Aerial 2

Illumination mode

DUV Light source power level: 45 Watt

Lens top tool connection

Scanning energy sensor calibration

Position of spot sensor on chuck 1 and 2: Layout 1

Z-Capture for low reflectivity wafer

Circuit dependent FEC

Focus monitoring

LS Focus node 3

Level sensor processing rack (LCSR)

LS PEMM Config

LS CPU Config: (3) CPUs

Recipe creator: Light

Report data category: Enhanced diagnostic

CDC

Proximity matching

MBDS Control

Enhanced exposure 1

XML report content level: Basic

Mark type: ASML Mark

Alignment laser configuration: (2) Color laser

Boards: ODB With ADB

Athena narrow marks Twinscan

Alignment sensor types: Athena narrow marks OM

Athena focus improvement 1

Maximum alignment speed: Setting 2

AACR Processing rack

Purging configuration 3

LCW Circuit set-ups

Clean air configuration

CT Miscellaneous rack

Clean air temperature controls: Driver and ACC

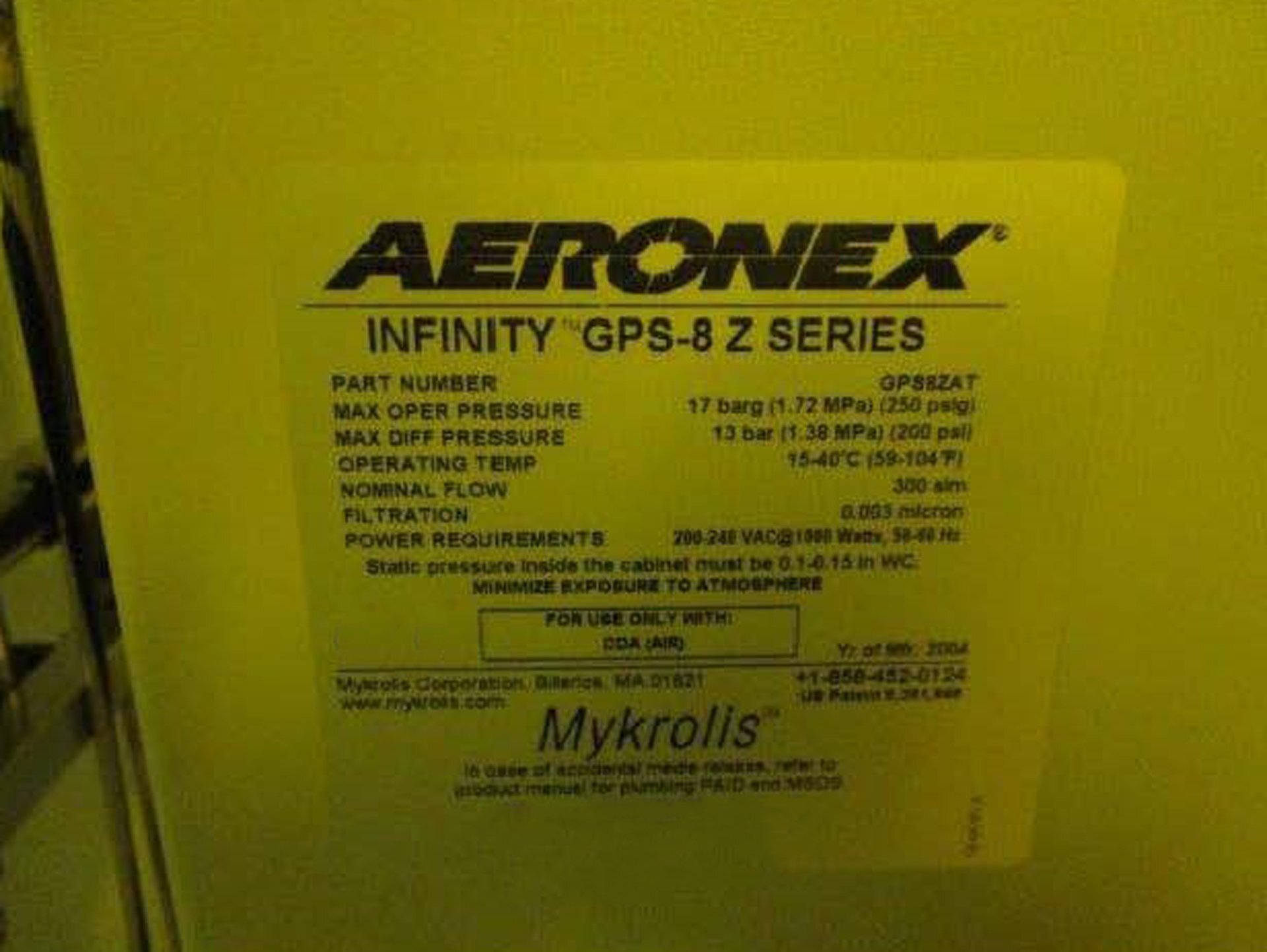

Purge hoods configuration: Compressed clean air and extremely clean dry air

Metro frame type: Type 1

Inlet restriction for clean air: Inlet restriction at right side

Reticle stage purged mini environment

Gas control unit type: High Flow (HF)

Lens circuit water flow: High

Motor circuit water flows

IFM Laser configuration: AOM Re-combo laser

Position control rack configuration: Rack configuration type 3

Position control power rack configuration type 3: Stages power rack upto E-spec

(5) Motion controllers

Position and motion control rack

Reticle stage short stroke X/Y11/Y12/Y21/Y22/Y11/Y11 amp: PADC 100 V / 16 A

Wafer stage short stroke 1 and 2 XY1/ XY2/XY3 amp: PADC 100 V / 16 A

Reticle stage short stroke Z1/Z2/Z3 amp: Pass low current 8.5 A

Wafer stage short stroke 1 and 2 Z1/Z2/Z3 amp: Pass low current 8.5 A

Reticle stage long stroke Y11/Y12/Y21/Y22 amp: 450 V, 20 A PAAC

Reticle balance mass 1/2 amp: 450 V, 20 A PAAC AT-pepD

Wafer stage long stroke E/M X amp: 400 V, 16 A PAAC AT-D

Wafer stage long stroke E and M Y1/Y2/CS amp: 400 V, 16 A PAAC AT-D

Wafer stage balance mass 11/12/21/22 amp: 325 V, 14 A PAAC AT-C

Pressure update rate: 2 Hz / 4 Hz

PEP Image streaming

Overhead reductions: LOR2

SMASH Reuse capture information in stage alignment

Wafer plane deviation check with focus monitoring

Wafer reject mode

Lens heating history in LH feed forwards

2D Grid correction

Ast offset correction in TIS LHFB/LOCO (Version 3)

NEXZ-Tilt per exposure

Projection lens: No off-axis slit

Enhanced throughput reticle alignment

Adjustable wavelength

Alignment report encryption

Stage alignment filter

Lot correction sequence: Type B

Lens heating feedback and calibration

Layout version number: TIS Plate 1 and 2 on chuck 1/2

Wavelength / Energy sensor

AM Controller hardware: SUCR

Lens heating

No polarization shaping element retractor hardware

No air gauge device

No leveling throughput improvement on measure side

Litho guide:

SAMOS Stray light test

PUPIL Measurement

FOCAL Measurement

Leveling verification test

ILIAS Sensor: Chuck 2

ILIAS Sensor type chuck 2: Multiple scan grid

SASO Robustness and fiber connectivity

Patch strategy: Patch level

Chuck

ZERO Fiducial: ILIAS MK2

XT Machine architecture

XT Architecture revision: Rev 1

No exchangeable pupil lens element

No sigma calibration

No sigma WIP preserving offset

CDC

Wafer handler productivity: Level 0

Does not include Hard Disk Drive (HDD)

2004 vintage.

ASML Twinscan XT 1250Dは、マイクロエレクトロニクス業界にリソグラフィーサービスを提供するように設計された高度なウェハステッパーです。これは、オランダのメーカーASMLによって設計され、構築されています。ASML TWINSCAN XT:1250Dは、従来のステップアンドスキャン技術と高度なステップアンドスキャン技術の両方を実行することができます。1250mmのスキャンフィールドサイズを備えているため、ゲート、フィン、ビア、深穴トレンチなどの大小の構造物を10:1のアスペクト比で素早く正確にパターン化できます。XT 1250Dのリソグラフィーエンジンは、ASMLが開発した262Wソリッドステートレーザーによって駆動され、大きな基板上に高解像度の画像を印刷することができます。11nm〜13。3nmの波長のEUVスペクトル範囲で動作し、さまざまなデバイスタイプを印刷するための汎用性を提供します。このシステムは、最大20ナノメートルの解像度でパターンを露出することができます。このユニットは、ナノメートルスケールの精度や静的または動的な登録技術など、さまざまなオーバーレイ技術をサポートしています。特許取得済みの「超高精度」ポジショナーを搭載しており、ユーザーはフィールド全体の基板またはレイヤーを正確に揃えることができます。さらに、オートフォーカスツールを備えており、常に最高のイメージング性能を保証します。TWINSCAN XT 1250 Dは低メンテナンス向けに設計されており、ソフトウェア制御のメンテナンスルーチンだけでなく、問題を簡単に検出して修正するための多数の組み込みツールと診断機能を備えています。また、リモートサービスオプションを提供しており、ユーザーは安全な接続を介して資産と通信することができます。Twinscan XT 1250Dは、さまざまな業界のリソグラフィ用途において比類のない性能、精度、汎用性を提供します。これは、高品質のマイクロエレクトロニクス部品を量産するための理想的なツールです。

まだレビューはありません