中古 G&N IDS 34 #142089 を販売中

URL がコピーされました!

タップしてズーム

ID: 142089

ヴィンテージ: 2007

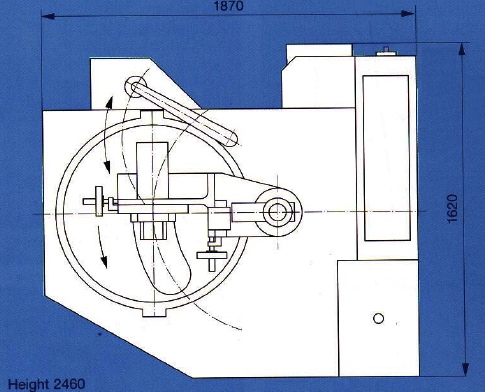

Inner diameter saw, 34"

Specifications:

Substrates capable: silicon, germanium, GGG, samariumcobalt, ferrite, glass, ceramic, semi-precious stones

Machine frame:

Vibration-free cast construction

Removable sheet metal covers on all sides

Swing type crystal holder: inner diameter saw blades up to 34" (860mm)

Frame rests on (6) shock and vibration absorbers

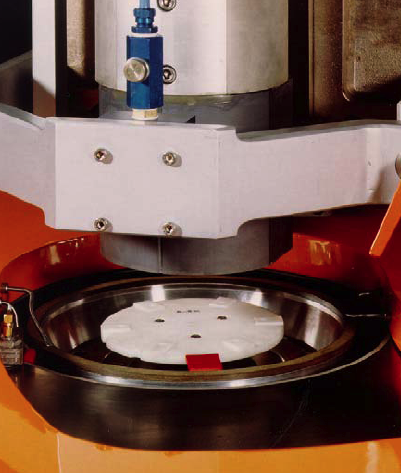

Blade mount:

Arranged horizontally

Axial and radial air bearings in optimum material combination

(2) Separate air connections for supply of air bearings

Air bearings sealed by labyrinth seals

Stationary inner cup: 260mm inner diamerter and (2) removable covers for control of the rotor disc

Massive rotor disc: heavy-duty special alluminum allow

Saw blade held by clamping ring

Spindle unit: horizontally adjustable, fitted to machine frame with (3) special screws

Supply pressure: 6 bar

Supply volume: maximum 30 m^3/hour

Axial runout of tensioning ring: less than 0.003 mm

Radial runout of tensioning ring: less than 0,015 mm

Radial runout of spindle pulley: less than 0.05 mm

If supply pressure drops below 4.5 bar, spindle drive is switched off via 2 air-lack differential switches, the monitors of axial and radial pressure

Top surface and inner diameter of supporting ring protected by welded stellite coat

Spindle drive:

AC motor: 3kW

Spring-pressure disk brake

Spindle drive: endless flat belt, grounding on both sides

Self-acting belt tensioning device

Power supply by electronic frequency converter

Spindle speed (infinitely variable): 500 to 1500 RPM

Spindle speed indication by 4-digit digital readout

Monitoring of the drive system by revolution control system

Machine automatically switched of if RPM is less than 900

Run-up time: less than 3 minutes

Run-down time: less than 2 minutes

Ingot infeed:

Arranged vertically to horizontal blade

Ingot clamping on the slide via holder, centering pin, quick clamping lever

Guide-ways of pre-loaded slide coated and grounded

Rolled ball screw pitch: 5mm

Top and bottom end position of the slide are limited by limit switches

Ingot dimensions:

Ingot dimensions: crystals up to 200mm ø and 570mm length

Orientation: ± 7° in (2) directions (scale graduation: 1 minute)

Thickness range: 0.6 to 6mm in 1µm increments

Index system repeatability: less than ±2µm

Infeed rates:

Up: 16 mm/sec

Down: 16mm/sec

Down: 2mm/sec

Cutting feed system:

Ingot feed mounted on massive, rigid, horizontal moving cast arm

Rests on large column and runs on (2) tapered polymer coated slide ways

Column clamped in a cast flange, screwed to machine frame

Cutting feed drive effected via ground ball screw, 2mm pitch, driven via disc gear motor, gimbal suspension of swing arm drive

Feed rate is infinitely variable, maximum 1800mm/min

Respective sawing positions can be preselected, monitored via potentiometers

Swing arm can be moved to extreme right hand position for saw blade or ingot change

Automatic wafer recovery system:

Wafer unloading within blade mount through 260mm dia bore of inner cup and air bearing spindle via a rigid linkage arrangement and a large surface vacuum chuck

Pick up chuck can be lowered 30mm, adjustable in end positions

Pick up chuck adjustable in (2) directions parallel to ingot to be cut

Additional height line feed

Vacuum and the back air for sawn wafer supplied thorugh linkage

Wafer transfer: blade bore

Swiveling handling arm with vacuum head takes sawn wafer from pick up chuck, lifts off and swivels through 900 to the rear

Wafer discharged in rear end position

Automatic switch off if wafer breakage or incorrect pick up

Possible control functions:

Set up:

All functions are operated individually, feed and infeed are interlocked

Single cut:

One feed motion without return

Automatic:

Fully automatic operation with automatic unloading

Pack slicing:

Adjustable for 1 to 999 cuts via three-decade selector switch

Signal bulbs:

Indication of faults: lack of air, vacuum, filter faults are indicated by signal lamps

Measuring and control unit Micro-Epsilon:

For monitoring and controlling saw blade with respect to saw quality and connected characteristics of saw blade

Supplies operator with information about possible unnecessary dressing procedures

Contactless gauging unit measures saw blade deviation during cutting cycle

Technical data:

Crystal range (dia x l): maximum 200 x 570mm

Packet cut of (2) crystals up to 125mm ø each

Sawblade diameter: 860 x 304mm

Rotational speed of spindle (infinitely variable): 500 to 1500 RPM

Spindle and drive:

Spindle: aerostatic bearings

Motor: 3kW, mechanical brake

Sawing feed:

Feed rate (infinitely variable): 0 to 150 mm/min maximum

Return speed: 1800 mm/min

Index system: 0.6 to 6mm

Indexing accuracy: 5 ± 2µm

Indexing speed: maximum 1500 mm/min

Orientation:

Adjustable: + 7° in two levels

Coolant:

Flow rate adjustable: up to 12 L/h

Indication: flow meter

Hydraulic system:

Pump: 0.55kW

Tank volume: 25 L

Pressure: 35 bar

Services:

Connected load: 7kW

Electrical supply: 220/380V, 50Hz

Compressed air: 6 bar

Features:

Automation:

Unloading device and vertical arrangement of crystal: automatic withdrawal of individual wafers without stopping machine

Simultaneous operation of other machines is possible

Predetermined number of wafers can be semiautomatically packet cut

Ergonomics:

Horizontal arrangement of sawhead allows for access and fitting of sawblade with (2) clamping collars

Precision:

Entire sawhead runs in radial and thrust aerostatic bearings

Adjustable on all levels

Electronic control and closed loop measuring system

Smallest infeed increment: approximately 0.6mm

Repeatability: < + 2µm

Rigidity:

Rigid construction and dynamically balanced rotating components

Demonstration machine

CE marked

2007 vintage.

G&N IDS 34は、ドイツのGerd&Netzgert社によって作成された最先端のスクライビングおよびダイシング機器です。このスクライブとダイシングシステムは強力に設計されており、多くの革新的な機能を提供しています。このユニットは、モータ駆動切刃の動きでダイシングの最高精度を確保するために、サーボ制御の空気圧クランピングシステムを使用しています。また、サーボ制御デバイスの位置決めとブレードアセンブリの組み合わせを使用して、切断操作を迅速に完了します。カッティングヘッドは、自動的に引き込むことができ、完璧な完成品を達成するのに役立ちます。パワフルなベースとは別に、IDS 34はパフォーマンスのための多種多様な機能を提供します。このマシンはシンプルでユーザーフレンドリーなコントロールユニットを備えており、コードと製品データを迅速かつ直接入力できます。そのユーザーインターフェイスは、開始から終了までの処理サイクルを管理するのに役立ちます。また、プロセスの進捗状況をリアルタイムで監視し、製品の最高品質を保証することもできます。G&N IDS 34は、オペレータフレンドリーな取り扱いのための準備ツールを備えているため、製品を別の製品に簡単に切り替えることができます。さらに、このツールは人間工学に基づいて設計された機械ベースを備えており、あらゆる作業環境に適しています。このスクライビングとダイシングアセットにより、加工の柔軟性も実現します。厚さ0。8mm、長さ35mmまで対応可能です。ダイシング領域は50 x 50mmまで設定でき、切断深度は12mmまで設定できます。ソーのテーブルの部分的な可動性は、最も複雑な輪郭をナビゲートするのに役立ちます。IDS 34には、ブレードとワークを正確にアライメントするためのレーザー測位モデルが搭載されており、より高い速度と精度を実現しています。さらに、最も複雑な部品でも正確に切断できます。G&N IDS 34装置は、非常に短いサイクルタイムで正確で正確な切断を提供する優れたソリューションです。革新的な機能と使いやすいオペレータインターフェースにより、このシステムは信頼性が高く、正確で高品質な製品を提供します。

まだレビューはありません