中古 VEECO / EMCORE E300 GaNzilla #141677 を販売中

この商品は既に販売済みのようです。下記の同じようなプロダクトを点検するか、または私達に連絡すれば私達のベテランのチームはあなたのためのそれを見つけます。

タップしてズーム

販売された

ID: 141677

MOCVD reactors / high efficiency GaN growth chambers, 2"

Set up for Sapphire, 21 pieces per run

EMCORE Confined Inlet FlowFlange with water-cooled cold plate

Removable 3-zone resistive Gen3 heater assembly with high temperature heat shields, insulators, and electrical feedthru's

EMCORE water-cooled Turbodisc susceptorless spindle rotation system

Integrated magnetofluidic rotation mechanism, motor and drive assembly

Complete reactor temperature management with water to water heat exchangers with temperature, flow, and water level alarms

Water-cooled baseplate assembly with thermocouple feedthru's and temperature regulation

Low differential pressure MFC's for alkyl distribution on FlowFlange

Pressure regulation network with low differential pressure MFC's for hydride and shroud distribution on FlowFlange

MFC purged 5-position viewport for in situ measurements

MKS 627 Baratron high temperature

Needle valves for gas purge of viewports and passthru flange

Mechanical span gauge for overpressure monitoring

DC power supplies for heater power

Dual differential pumped O-ring seals for reactor flanges with pump and pressure monitor

E300 GaN loadlock and platter transfer system:

High vacuum stainless steel loadlock chamber with viewports and (2) dwell stations for high throughput capability

(3) high purity SiC coated 12" wafer carriers

(1) blank SiC coated wafer carrier for temperature calibration

Pneumatically controlled, interlocked gate valve for isolation between growth chamber and loadlock chamber

GENMARK GB9 vacuum robot for wafer carrier transfer

Stainless steel end effect for robot transfer

MKS 622 Baratron for pressure measurement of loadlock chamber

Toxic gas sampling port

Mechanical span gauge for overpressure monitoring

Integrated glovebox wafer loading chamber with turntable

Interlocked, pneumatically controlled gate valve for isolation between loadlock chamber and glovebox

Automated antechamber with dedicated pump for wafer transfer

Regenerable Nitrogen purifier / recirculation system with automated control

Moisture monitoring with alarm ability

Storage shelves for extra wafer carriers / substrates

E300 pump system for growth chamber:

EBARA A70W process exhaust pump (297 cfm), water cooled motors, nitrogen purge system, microprocessor with alarm / control via digital interface

E300 vacuum exhaust system

3” exhaust line

Manual ISO-80 3” ball valve

Dual disposable high temperature particle filter

Pneumatic KF-40 ball valve

KF-40 leak detector port

Electronic pressure transducer

Throttling gate valve

Overpressure protection via switch gauge

E300 GaN loadlock pump system:

Turbomolecular pump for high vacuum

Pneumatic isolation 3” gate valve

ISO-100 protective stainless steel screen

High vacuum ion gauge

High vacuum convectron gauge

Low pressure nitrogen regulator

KF-25 leak detector port

Alkyl evacuation line

Dry scroll pump

(7) additional wafer carriers

SEKIDENKO 3-sensor pyrometer:

Single color optical fiber temperature measurement system

(3) pyrometer sensors

(3) optical fiber cables

Digital temperature display

Epimetric in situ monitor with dual head (EPI/2):

Absolute growth rate measurement

Real-time process stability verification

Includes computer and custom software

Standard system assemblies:

EMCORE E300 GaN gas panel sub assembly:

Switchable H2/N2 gas injection manifold for alkyl sources

High conductance H2, N2, and NH3 injection manifold

Metal sealed mass flow controllers for gas distribution

Electronic pressure measurement

Fast switching pneumatic valves for gas distribution

High purity fitting and tubing

1/8” bubbler legs in and out of each source

E300 uniframe system cabinet:

175” steel growth cabinet

Includes space for: growth chamber, loadlock, gas panel, refrigerator baths, vacuum system, and electronics

Interlocked clean lexan soft-seal doors

Solid panel soft-seal doors with louvers

Water cooled bath manifold

Gas panel: Alkyl sources:

(2) Cp2Mg single bubbler dilution network source manifolds:

Five valve high-purity welded manifold

Metal sealed mass flow controllers for source, carrier push gas, and diluted gas to injector manifold

Metal sealed integrated pressure controller

Integrated spool piece for binary gas monitor

(2) TMIn dual bubbler push configuration source manifold:

Five valve high-purity welded manifold

Metal sealed mass flow controllers for source, carrier gas push

Metal sealed integrated pressure controller

Integrated spool piece for binary gas monitor

TMGa dilution network source manifold:

Five valve high-purity welded manifold

Metal sealed mass flow controllers for source, carrier push gas, and diluted gas to injector manifold

Metal sealed integrated pressure controller

Integrated spool piece for binary gas monitor

TMAI standard source manifold:

Five valve high-purity welded manifold

Metal sealed mass flow controller

Metal sealed integrated pressure controller

Integrated spool piece for binary gas monitor

TMGa standard source manifold:

Five valve high-purity welded manifold

Metal sealed mass flow controller

Metal sealed integrated pressure controller

Integrated spool piece for binary gas monitor

TEGa standard source manifold:

Five valve high-purity welded manifold

Metal sealed mass flow controller

Metal sealed integrated pressure controller

Integrated spool piece for binary gas monitor

(2) NESLAB RTE-221W water-cooled liquid bath:

20.5 liters reservoir volume

Four digit digital display, -23°C to +150°C

Water-cooled heat exchanger

(2) NESLAB RTE-111W water-cooled liquid bath:

7 liters reservoir volume

Four digit digital display, -23°C to +150°C

Water-cooled heat exchanger

Phantom line for alkyl injector block:

Direct input metal sealed MFC to injector block

NESLAB RTE-211W water-cooled liquid bath

12.3 liters reservoir volume

Four digit digital display, -23°C to +150°C

Water-cooled heat exchanger

Gas panel: Hydride sources:

SiH4 single input with dilution manifold:

High purity welded manifold with interlocked source and purge valves

Metal sealed source calibrated MFC’s with carrier gas calibrated dilution network

NH3 dual input hydride manifold:

High purity welded manifold with interlocked source and purge valves

Metal sealed source calibrated MFC’s

Electronics and control:

System electronics and control modules, enhanced:

EMCORE standard control modules for substrate rotation, reactor temperature control, reactor pressure, system logic control and pump activation

Integrated power load center with emergency power off switch

+15. -15. +24 VDC power supplies

Dual microprocessor units with analog and digital control boards, input boards, and RS232 / Ethernet ports for communication

EpiView control and monitoring software:

Graphical display windows for all gas panel, growth chamber, and exhaust components

User-configurable parameters for valve states, analog scales and set points

Data logging and viewing with configurable data rate and signal selection

Export of data files to Microsoft Excel for analysis and presentation, with automatic data compression

On-line help

Advanced troubleshooting and diagnostic tools, automated maintenance

Report generator for run analysis

Event recording of system status and alarms

Definable levels for system security

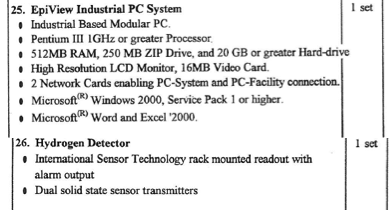

EpiView industrial PC system:

Industrial based modular PC

Pentium III 1 GHz or greater processor

512 MB RAM, 250 MB ZIP drive, and 20 GB or greater hard drive

High resolution LCD monitor, 16 MB video card

(2) Network cards enabling PC system and PC facility connection

Microsoft Windows 2000, service pack 1 or higher

Microsoft Word and Excel 2000

Hydrogen detector:

International sensor technology rack mounted readout with alarm output

Dual solid state sensor transmitters

Currently installed and powered on in cleanroom

2004 and 2005 vintage.

VEECO/EMCORE E300 GaNzilla原子炉は、高品質の中高温ガリウム窒化物(GaN)材料を成長させるための強力な技術を組み合わせた最先端の結晶成長装置です。GaNzillaリアクターは、電子サイクロトロン共鳴(ECR)プラズマ源と高度な電子堆積システムを備えており、GaN材料の再現可能な単結晶層層別エピタキシーを作成します。これにより、材料の成長プロセスを正確に制御できます。GaNzillaで使用されるECR源は、幅広い背景で高密度、高エネルギーのプラズマを生成することができます。これは、調整可能な周波数磁界発生器、特別なカスプ・トラップ、および調整可能なガス流量ユニットを含む専用ハードウェアの組み合わせにより、高イオンエネルギー、高い蒸着速度、低い粒子閉塞をもたらします。ECRソースに加えて、Electronic Deposition (EDS)マシンは、蒸着プロセスを正確に制御します。EDSツールには独自のモル触媒ソリューションが使用されており、調整可能なマイクロ波場発電機を使用することで、低圧、低消費電力、低温CVDプロセスを実現しています。これにより、標準材料よりもはるかに低い温度でGaN層を堆積させることができ、高品質の材料とより良い収率をもたらします。VEECO E300 GaNzillaには、GaN材料を成長させるための理想的な選択肢となる他の多くの機能が付属しています。これらの機能には、タッチスクリーン付きのユーザーフレンドリーな液晶ディスプレイ、薄型設計の真空チャンバー、ステンレス構造、オペレータの安全性を確保するための多数の安全機能が含まれます。EMCORE E300 GaNzillaは、研究および産業用途の両方に使用できる汎用性と強力な原子炉です。GaNzillaは、高品質の材料と安全で効率的な成長のための資産を備えており、幅広い用途のためのGaN材料の生産に最適です。

まだレビューはありません