中古 TAMARACK 161B #165720 を販売中

URL がコピーされました!

タップしてズーム

ID: 165720

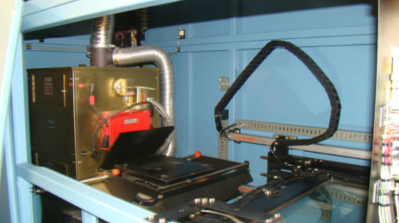

Printed circuit board exposure system

Specifications:

Semi-automatic machine

Used to provide rapid and precise alignment of large PCB panels

Components:

Panel alignment / exposure station

Collimated illuminator

Pneumatic valves

Sequencer

Alignment / exposure station:

Provides the facilities for aligning the P.C.B. panel with respect to the artwork and providing vacuum contact for exposure

Mylar cover frame is hinged toward the rear of the machine to allow raising of the frame for changing the panel and artwork

Collimated illuminator:

Provides a condensed beam of ultra-violet light of uniform intensity for use in exposing the panel

Shutter within the illuminator opens for a preset interval to accomplish the exposure

(2) modes of exposure control are available to operate the shutter: constant time and constant energy

Constant time is set in on the exposure time in seconds

In the constant energy mode, exposure energy in millijoules per centimeter squared (mJ / cm) is set on the exposure energy thumbpot

Light source for the collimated illuminator: high pressure mercury arc lamp mounted in a forced air cooled housing

Housing is designed to contain and withstand lamp explosion

Lamp is positioned near the first focus of an ellipsoidal reflector

(3) Thumbscrews provide the means of moving the lamp along the X, Y, and Z axes in order to obtain the proper lamp position

Ellipsoidal reflector directs the reflected light toward a distant second focus thus avoiding the possibility of lamp damage due to reflection of energy onto critical parts of the lamp

Ultra-violet light from the ellipsoidal reflector is turned twice to reach a second focus located at the lenticular integrator

Dichroic mirrors which turn the ultra-violet light pass most visible light and infra-red energy which are thus dissipated as heat within the lamp house and exhausted out of the system

Lenticular integrator, located at the second focus of the ellipsoidal reflector, collects the ultra-violet energy and directs it toward the collimating mirror in such a manner as to approximate a point source of light

Mirror collimates the light from the integrator so as to form a beam of light exhibiting uniform intensity over its beam width

Shutter which controls panel exposure is located just ahead of the lenticular integrator

An associated panel switch provides the means of holding this shutter open for the purpose of lamp intensity and focus adjustments or placing it under the control of the digital timer or integrating exposure controller during panel exposure

Panel size: 19" x 25"

Pneumatic panel:

Located inside the machine above the side control panel

Panel supplies air pressure and vacuum to all air operated systems through the machine

Solenoid valves are operated on 24V DC and controlled from the sequencer and pushbuttons

Sequencer:

Control of the 161B is accomplished by a Mitsubishi programmable controller located on the pneumatic panel

Manual switch panel is also mounted on the pneumatic panel

Side control panel:

Used to start and stop all functions of the machine

Main power contactor enable

Lamp ignitor

Lamp exhaust temperature, alarm and lamp meter (resettable)

Machine control power

Front control panel:

Timer and integrating exposure control switch are used to pick the mode of exposure

If the machine is used in the time mode, the exposure time in seconds must be set

When constant exposure energy is required, the IEC will measure the quantity of energy at the panel / exposure plane and control the shutter to maintain the same exposure energy independent of light intensity

Bullnose:

Contains a light table to aid alignment of the artwork to the substrate

The start cycle switches must be actuated simultaneously to begin print drawer movement

Top and bottom vacuum switches, gauges, emergency off switch and final cycle switches are also on the bullnose.

TAMARACK 161Bは、高解像度の高品質マスクを迅速に製造するために設計された先進的なマスク生成および生産装置です。このシステムは、基本的なデバイスから3Dステレオリソグラフィーマスクまで、さまざまな種類のマスクを製造することができます。161Bは最新の技術を使用しており、マスクに必要な物理レイヤーを作成するために使用されるレイヤー定義ファイルを生成することができます。このユニットは、シンプルで効率的なマスク生成のための強力な光学アライメントマシンと、最適なアライメントとマスク品質のための高度な画像処理アルゴリズムを利用しています。このツールには、解像度と生産速度を向上させるための最先端の電子ビームリソグラフィ資産も組み込まれています。TAMARACK 161Bは、迅速なスループットと簡単な操作のために設計されており、あらゆるタイプのマスク作成アプリケーションに最適です。このモデルは、イメージング精度と速度の向上、複数層の正確なアライメントと登録、材料コストの削減、マルチレベルのマスク生産のサポートなど、既存のマスク生産システムに比べていくつかの重要な利点があります。堅牢な設計と統合機能により、161Bは幅広い業界のデバイスメーカーの要求に応えることができます。この装置は、あらゆるレベルの回路の撮影、リソグラフィック印刷、イメージングなど、さまざまな作業を行うことができます。また、CAD (Computer Aided Design)機能を搭載した完全自動マスク生成プロセスを提供し、複雑な回路やアーキテクチャの開発を容易にします。TAMARACK 161Bの統合イメージデータ管理ユニットは、ユーザーが簡単かつ正確に設計を保存および取得することができます。また、故障解析、テスト測定、プロセス統合などの追加機能を組み込むことができます。マスク製造技術の最新の進歩に追いつくために、161Bは定期的にアップグレードと更新を受け取ります。お客様には、ソフトウェアアップデート、定期的なメンテナンス、専用のカスタマーサービスへのアクセスが提供され、手間がかかりません。TAMARACK 161Bは、信頼性が高く、効率的で費用対効果の高いマスク生成および生産ツールであり、すべてのマスク生産ニーズに最適な資産です。

まだレビューはありません